Supercharge!

0 to100 m.p.h. in 14 seconds in a HR Holden

by Eldred Norman

Chapter 2 - Types of Superchargers [continued]

The Vane Type Supercharger

It consists of a cylindrical casing with a port on either side but not necessarily diametrically opposed. For the sake of good breathing the ports usually run the whole length of the casing.

There is only one rotor, generally about three quarters of the diameter of the casing. It is mounted at both ends in eccentric end plates so that rotating about its longitudinal axis it just clears the inside diameter of the outer casing. The point of closest approach to the casing should always be near the outlet port. The arrangement of the inlet port is usually such that the centre-line of the port is about 90 degrees from this point. The position of the ports can have a considerable influence on noise level as well as other results.

The rotor itself is slotted for the whole length with usually four equally spaced slots. These are cut as partial tangents to the circumference so that the direction of rotation tends to reduce the frictional load on the tips of the vanes which occupy the slots. The vanes or blades are usually made of cotton-reinforced Bakelite.

In operation these vanes remain in contact with the casing because of centrifugal force caused by the rotation of the rotor/ blade assembly. These vanes must slide freely in the slots of the rotor. In fact when fitting them they must be a ‘flop’ fit when dry.

Owing to the eccentric arrangement of the rotor when it is turned there are always two vanes expanding away from one port, the inlet and two being forced into their slots on the opposite side and compressing the included charge until the outlet port is reached.

The action of the vanes themselves makes an interesting study during the cycle of operation. At first sight it appears that they have a reciprocating motion in a radial direction. This is not so, since during their cycle they remain in contact with the outer casing which is of course stationary. Actually their respective centres of gravity oscillate laterally at right angles to the radial forces.

If made with careful tolerances and with the correct arrangement of porting this type of supercharger can pump at quite high pressures. Using cast iron vanes instead of fibre, and well lubricated they are taking an increasing share of the air-compressor market. They have been used for many years as vacuum pumps for milking machines.

When designed as superchargers for cars the positioning of the ports and their sizes are somewhat different from those of the industrial unit.

First, since they are intended to operate at comparatively high r.p.m. the port apertures are widened so that they occupy more of the casings circumference. This is particularly so in the case of the inlet port. If the centre of the inlet port is moved too far from the nearest point of the rotor to the casing, the unit becomes very noisey since the vacuum created by the vanes on the inlet side causes an implosion when the port is reached during rotation. If the port does not extend far enough around towards the point of maximum rotor clearance from the casing, filling will suffer particulary at high speeds. If it is carried too far, blowback will occur into the carburetor at low speeds in exactly the same way as it occurs with a hot cam in a racing engine.

Now because the vanes always remain in contact with the casing very little leakage can occur past the vanes. This means that the pressure is likely to be more constant than is the case with the Roots type.

One of the chief problems with this type of supercharger is that of lubrication. Mechanically it is subject to fairly high frictional loads in various of its components. This can generate undesirable heat as well as cause unnecessary wear. There is no doubt that the simplest form of lubrication is the addition of a specified amount of oil to the fuel supply which must pass through the supercharger from the carburetor. Practical experience has convinced me that this method is not only the simplest, it is the best. Any practical system which introduces a metered supply via the induction does not adequately lubricate the surfaces of the vanes in the slots since centrifugal force tends to keep any such oil droplets on the inner surface of the casing. This provides good lubrication for the tips of the vanes but that is not sufficient. Heat generated at this point can be dissipated by adequate cooling of the casing, but heat generated by the friction of the vanes in the slots can only be lost to the air/fuel mixture which is passing to the motor, since it is impossible to conduct more than a fraction of the rotor’s heat through the bearings.

The heat generated in this type of unit comes from three sources. From the friction of the vanes on the casing due in part to centrifugal force; and to the friction in the slots due to the pressure loading on the vanes; and also to the heat generated by the compression of the charge itself. This last is adiabatic and is common to all types of superchargers. Not just the vane type.

In the design of this type of unit not much can be done about the heat generated from friction caused by the charge pressure against the vanes, other than to see that the outlet port covers a sufficiently large section of the circumference to prevent a too high pressure build up within the supercharger before the discharge to through the port. In effect it is not necessary to compress the charge to perhaps 25 p.s.i and then discharge it into a manifold where the pressure is only perhaps a third of this.

The friction caused by centrifugal force can be very much reduced by using a supercharger with a capacity sufficiently large to make high r.p.m. unnecessary. The forces actually increase by the square of the proportion of the increase in r.p.m. , so everything is gained by using a large supercharger and low revs. If this rule is observed the vane type does not take a great deal more power to operate than a Roots type.

In 1954, driving a supercharged Triumph TR2, I finished 4th in the Australian Grand Prix. On this car I used a “boost’ of 12lbs. The supercharger was a G.M. 271 Roots type unit operating at 1.1 times engine speed and driven by four ‘A’ section V belts. By the end of the race belt-slips had caused a fall in boost to a maximum of 8 lbs. Naturally I had to ‘nurse’ the belts by not using full throttle at this stage. My present Holden is some 50% greater in capacity than was the Triumph. I am using a 10 lb. supercharge from my type 110 vane type supercharger and drive it with only two ‘A’ section belts. Under these conditions the vane type is putting out almost 40% more air/fuel than did the Roots with twice the number of belts. Certainly the car is not being raced which is an enormous difference. But my belts last at least 5000 miles of normal road use. Detractors of the vane type supercharger have usually only seen the wrong unit on the job.

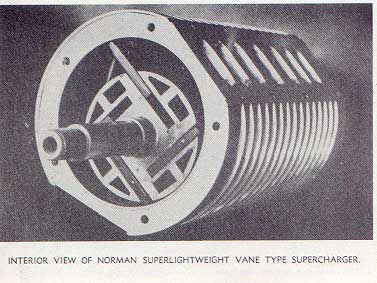

This type of supercharger has also got a bad name as many of them are made with aluminium rotors, both for reasons of lightness and of cost. Unfortunately this material has very poor wearing qualities as well as causing high frictional loads. The steel rotor has almost eight times the life of its aluminium counterpart and involves much less friction. Also the steel rotor can be nitrided by a new low temperature process which more than doubles the life again, as well as increasing the resistance to fatigue stresses. The steel rotor can be made almost as light as aluminium by a rather complex machining process.

If weight is of importance for a particular job there is little to choose between the vane and the Roots.

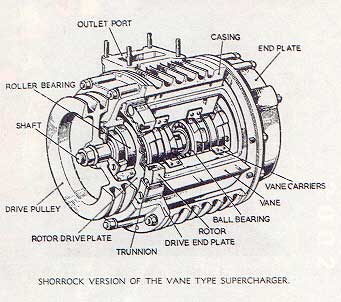

There is a vane type supercharger made by Shorrock of England, which almost eliminates all friction losses with type of unit. It is quite complex and for that reason I will make no effort to describe it other than to say that the friction of the blades on the outer case is entirely eliminated by enclosing them in a drum which runs on a bearing at either end and rotates with the rotor so as to just clear the outer casing. The blades, usually six in number, are not set tangentially in the rotor, but radially and they rotate with the drum.

Mechanically this is at least as efficient as the Roots but has a tendency to over-complication and is of course more expensive to manufacture than the more simple sliding vane type also it is some what heavier and more bulky than the latter.

As mentioned previously in the section on the Roots type supercharger, the vane type is more efficient adiabatically. This is because the charge being introduced is gradually compressed within the supercharger before being discharged into the pressure manifold. By correctly positioning the outlet port the pressure before discharge can be brought to almost an exact balance with that in the manifold so that there is an uninterrupted flow through the supercharger. This reduces the noise level as well as contributes to the overall efficiency.

I am often asked about wearing qualities of the different types of superchargers and maintenance costs.

The cheapest to operate would undoubtedly be the axial and the centrifugal type since they have no wearing parts other than belts and bearings. The Latham does not even use any gears to step up r.p.m. It uses a thin flat belt running on a large crankshaft pulley and driving a very small pulley on the supercharger shaft. The small pulley is so small that it is probable that belt life would not be very great; also the very high r.p.m. of the rotor would tend to give a short bearing life.

The Paxton type centrifugal would probably have a longer belt life but of course there are gears to wear out ultimately. However, it is well built and if correctly lubricated should certainly last 100,000 miles with a few bearing replacements.

The Roots type should also have quite a long operating life if carefully maintained. This last applies particuly to the gear train and its adequate lubrication. If backlash is allowed to develop in the gears the rotors will touch and score each other and much efficiency will be lost. If the rotors and gears had to be replaced at any time they would be expensive. The rotors and gears for the 671 GM blower cost about $500.00 to replace, but of course this is a large size.

The sliding vane would be the most expensive to operate. If well built with a steel rotor and hardened liner in the casing it will require a new set of vanes about every 20,000 miles. These will cost about $10.00 the set. It will require a new liner after 50,000 miles, cost about $30.00. The rotor should last 100,000 miles.

In taking count of the cost of operation it must also be remembered that the vane type will require oil to be added to the fuel in the ration of a pint to seven gallons of petrol for lubrication of the supercharger. This all adds to the cost.

With reference to this oil however it must not be forgotten that the engine itself will require a pint of oil to twelve gallons to avoid upper cylinder dryness, no matter what type of supercharger is used.

This is a special Technical Info article, reprinted from the original (and rare!) book that was supplied with superchargers purchased from Eldred Norman, Aussie racing legend and manufacturer of Norman Superchargers.

Although not a common method of modifying an FE or FC, the theory and information about fuel induction, carburettion and so on is fascinating. Many thanks to Tony (IhadaV8) for obtaining the book and providing it to us. Tony in turn thanks Mike Norman, for supplying a copy of his father's book.

Important Note: This document is intended as a guide for those persons interested in repairing or modifying their vehicle. The FE-FC Holden Car Clubs of Australia take no responsibility and accept no liability for the information contained herein. You must ensure that all work carried out and/or modifications made to your vehicle are legal in your state, and we recommend you contact an engineer or your local Traffic Authority for further information.

If you have a technical question about repairs or maintenance on your FE or FC, please post a question on our Discussion Forum.

Home || NSW || Queensland || SA || Victoria || Sign the Book || Chat about FE/FCs || Nationals || Tech Data