Supercharge!

0 to100 m.p.h. in 14 seconds in a HR Holden

by Eldred Norman

Chapter 2 - Types of Superchargers [continued]

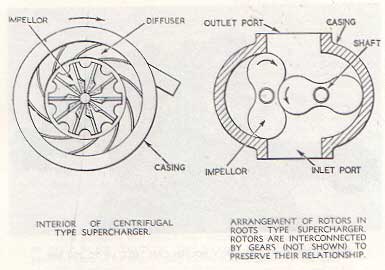

The Roots Type Supercharger

This works on exactly the same principle as the small gear pump common to the oiling system of most car engines. However, instead of having two gears which actually touch and form a single drive unit, in the supercharger there are two rotors. These rotors may have two or more ‘lobes’ so that in cross section a rotor resembles a dumb-bell if it is a two lobe type, or a cloverleaf if it has three lobes. They are also made with four lobes. These rotors are intermeshed as are gears but do not quite touch each other. They rotate about two separate axes which are parallel and just far enough apart to prevent contact between the lobe of one rotor and the corresponding recess or gullet in the opposite number. The relative position of lobes and gullets are maintained by a separate gear train outside the casing. These gears are themselves usually enclosed and lubricated from the car’s oiling system.

The casing which is oval in form to include the two arcs described by the tips of the lobes of the rotors, is machined internally so that there is about .010 clearance of the rotors. The latter of course rotate in opposite directions, as do the gears when meshed in an oil pump.

The pumping action consists of the transference of that portion of air supplied by the atmosphere, and which occupies the spaces between the lobes of the rotors on the inlet side, to the outlet side by the action of rotation. The air can only travel in one direction as its return is blocked by the intermeshing of the two rotors at the centreline.

If made carefully with fine tolerances, this type of supercharger is very efficient for pressures up to about 10 lbs. At greater pressures than this an appreciable amount of heat can be generated due to leakage past the rotors and through their clearance with the casing. The Roots can of course handle dry air satisfactorily, although the drive gears themselves must be supplied with lubrication. This is usually done from the engine oiling system by means of a small metered pipe from the pressure gallery. The return is usually by gravity via a much larger pipe to the sump or tappet cover plate.

With this type of supercharger it is normal to inhale from the carburetor through the unit itself and pass the air/fuel mixture on to the motor. The advantage of this is that the petrol acts as a coolant and the supercharger operates with greater efficiency. With the appropriate supercharger geared so as not to exceed about 7000 r.p.m. fuel seperation is not excessive. Some seperation undoubtedly does take place, but moderately high manifold and valve port velocities can usually correct such seperation as does occur.

It is perhaps appropriate to mention here that although both the Roots and the centrifugal, and also the axial type superchargers can operate without actual lubrication, a factor which has undoubted appeal, it is advisable to add a percentage of lubricant to the fuel of all supercharged motors, no matter what type of supercharger is used. The supercharged engine normally tends to have a slight boundary lubrication problem at the top of the cylinder. Owing to the fact that all four strokes of the piston are pressure strokes there is less opportunity for oil to work up past the piston, particulary if the engine is being worked hard. In this instance there is actually no ‘suction’ stroke as there is with the atmospheric motor. A pint of ordinary engine oil added to each twelve gallons of fuel in the tank will take care of this problem and have a very beneficial effect on the life of the motor. It has no effect on the spark plugs nor does it cause any smoking from the exhaust.

The Roots supercharger is probably the best all round type for normal road use, including road racing. It is reasonably efficient over the whole of its operating range and can give a useful pressure at quite low r.p.m. In fact it’s operating efficiency is almost identical with the average motor’s inefficiency. This is important as it means that compression pressures can remain almost constant over a very wide range, and enables maximum energy to be obtained from each gallon of fuel. The Roots if correctly geared does not tend to outrun the engine’s capacity to receive. This latter is the great weakness of the centrifugal and axial flow units which far outrun the falloff in engine breathing, and can cause pinking and even detonation at high speed when it is apt to be unheard because the general noise level is so high.

The Roots is not a cheap supercharger as it is difficult to manufacture. A number of the components can only be produced with very special equipment. Also it must be treated with care, as tolerances are critical if it is to perform well.

One of the worst faults with the Roots supercharger is the fact that it tends to cause bad flow pulsation Because it works by transference of the charge at atmospheric pressure to a manifold at a greater pressure, there can be a very considerable bounce-back as each separate ‘chunk’ of air is introduced. This appreciably reduces the overall efficiency and results in an adiabatic efficiency of only about 50% as against that of the vane type’s 70% and the centrifugal’s 90%. Also it is largely responsible for the rather high noise level of the Roots.

In an effort to reduce this pulsation effect the Roots is often made with helical rotors to try to provide a more continuous flow. Also the outlet and inlet ports are commonly shaped so that the openings form a helix to the axis. Neither of these methods is entirely successful but they are at an improvement.

[continued...]

This is a special Technical Info article, reprinted from the original (and rare!) book that was supplied with superchargers purchased from Eldred Norman, Aussie racing legend and manufacturer of Norman Superchargers.

Although not a common method of modifying an FE or FC, the theory and information about fuel induction, carburettion and so on is fascinating. Many thanks to Tony (IhadaV8) for obtaining the book and providing it to us. Tony in turn thanks Mike Norman, for supplying a copy of his father's book.

Important Note: This document is intended as a guide for those persons interested in repairing or modifying their vehicle. The FE-FC Holden Car Clubs of Australia take no responsibility and accept no liability for the information contained herein. You must ensure that all work carried out and/or modifications made to your vehicle are legal in your state, and we recommend you contact an engineer or your local Traffic Authority for further information.

If you have a technical question about repairs or maintenance on your FE or FC, please post a question on our Discussion Forum.

Home || NSW || Queensland || SA || Victoria || Sign the Book || Chat about FE/FCs || Nationals || Tech Data